Heavyweight concrete

Heavyweight concrete defined as a concrete having bulk density ranges between 3360kh/m3-3840kg/m3. Heavyweight concrete produced by using heavyweight aggregates. Aggregates used for heavyweight concrete can be natural such as barites or magnetite. Also, manufactured aggregates can be used, such as iron or lead shot. Heavyweight concrete can be used to prevent the seepage from radioactive structures such as nuclear stations, laboratories, and hospitals. Radioactive emissions have adverse effects on living organisms. Severe radiation can cause death.

The water-cement ratio for heavyweight concrete is important, and it should be determined carefully to produce a dense concrete with low permeability. The favorable w/c for heavyweight concrete is 0.40. Another important point is the cement volume. The cement used in heavyweight concrete should be enough to ensure impermeable concrete that can resist the seepage of radioactive emissions. Also, the amount of cement used should be low enough to prevent shrinkage cracks. The recommended cement dosage should be more than 350 kg/m3.

A new type of heavyweight concrete developed recently. This type of concrete used as soundproof. The aggregate for this type of heavyweight concrete is made from iron with a thin layer of rubber. Aggregates will play the role of a local resonance unit. Figure no:2 showing an experiment conducted to evaluate the sound loss for different construction materials. we can notice that at 180 HZ sound transmission loss for heavyweight concrete is 45 dB which is higher than other construction materials. therefore, heavyweight concrete can be used effectively to block sound at specific frequencies

Heavyweight concrete can be transported and placed using conventional equipment. The amount of concrete carried by the mixer will be limited by the density. The equipment used to transport and pump concrete will have a higher wearing rate. Formwork used to support heavyweight concrete should be designed to carry the huge pressure generated during placing and compacting heavyweight concrete. Also, more efforts required to compact heavyweight concrete. A larger number of vibrators should be used, and it should be placed closer to each other during the compacting of concrete.

The water-cement ratio for heavyweight concrete is important, and it should be determined carefully to produce a dense concrete with low permeability. The favorable w/c for heavyweight concrete is 0.40. Another important point is the cement volume. The cement used in heavyweight concrete should be enough to ensure impermeable concrete that can resist the seepage of radioactive emissions. Also, the amount of cement used should be low enough to prevent shrinkage cracks. The recommended cement dosage should be more than 350 kg/m3.

A new type of heavyweight concrete developed recently. This type of concrete used as soundproof. The aggregate for this type of heavyweight concrete is made from iron with a thin layer of rubber. Aggregates will play the role of a local resonance unit. Figure no:2 showing an experiment conducted to evaluate the sound loss for different construction materials. we can notice that at 180 HZ sound transmission loss for heavyweight concrete is 45 dB which is higher than other construction materials. therefore, heavyweight concrete can be used effectively to block sound at specific frequencies

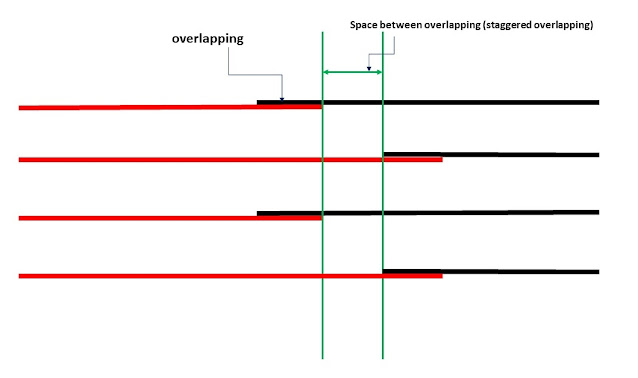

Figure 1

Figure 2

Heavyweight concrete can be transported and placed using conventional equipment. The amount of concrete carried by the mixer will be limited by the density. The equipment used to transport and pump concrete will have a higher wearing rate. Formwork used to support heavyweight concrete should be designed to carry the huge pressure generated during placing and compacting heavyweight concrete. Also, more efforts required to compact heavyweight concrete. A larger number of vibrators should be used, and it should be placed closer to each other during the compacting of concrete.

Comments

Post a Comment