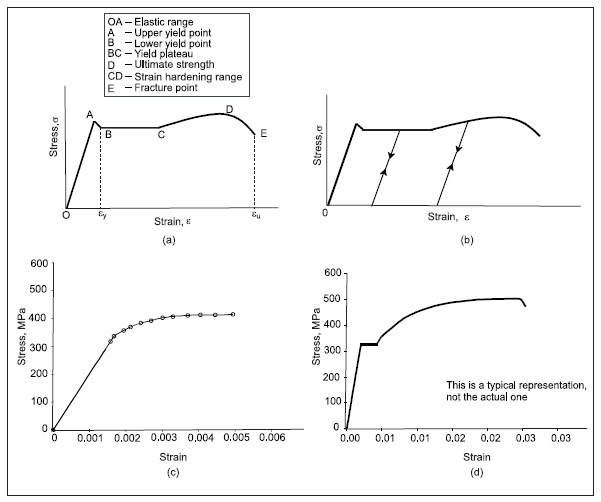

Ductility of reinforcing steel

Ductility is an important property of steel reinforcement. Ductility is the ability of the material to undergo plastic deformation before failure. The ductility of reinforcement is related to the elongation property. The ductility of reinforcement ensures safer and durable structures. Material that undergoes little or no plastic deformation is known as a brittle material. Brittle reinforcement can cause sudden structure failure because it doesn't undergo any plastic deformation before failure. Figure 1 The ductility factor for reinforcement can be computed using the following equation: µ=ϵu/ϵy where, µ is the ductility factor ϵu is the ultimate strain ϵy is the yield strain In figure no:1-a, we can see the stress-strain curve for mild steel. The mild steel has well-defined yield stress and strain, as shown in the stress-strain curve. The reinforcing bar can recover all the elongation if the applied stress is lesser than the yield stress. This portion of the curve is kno...