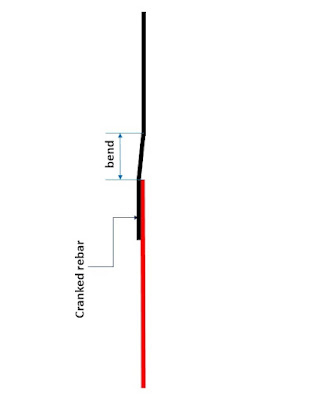

why do we use cranked rebar at rebar overlapping?

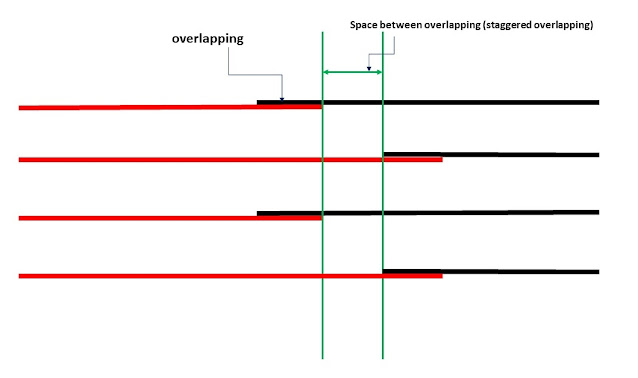

Cranked bars are produced by slightly bending the reinforcement bar before the overlapping zone then straightening it at the overlapping zone, as shown in figure no:1. The main purpose of this practice is to reduce the congestion of reinforcement at the overlapping zone for structure members with a high amount of reinforcement. The use of crank bars will give flexibility in fixing and arranging reinforcement to reduce the congestion, which helps create a larger space between reinforcement rebars. The spacing between reinforcement rebars should be sufficient to allow smooth concrete placement. Small spacing of reinforcement rebar will work as a screen that will enable the concrete paste to pass through it and stop aggregate, which results in concrete segregation. Therefore, cranked rebars can be used to slightly reduce the congestion of reinforcement rebars and increase the spacing between rebars. Figure no:1