why do we overlap steel rebars??

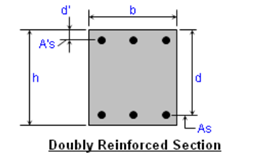

First, we should know that steel rebar comes in standard length such as 12m. using very long reinforcement is impractical because it will result in difficulties in handling reinforcement by steel fabricators. Also, longer rebar is heavier and difficult to lift and move. So for a long structure such as a slab, we require a reinforcement length that is more than the standard reinforcement. We can't use a single piece of rebar for a specific length for such a structure, so we use two or more steel rebars to cover the entire length of the structure. Clearly, the point of joining these rebars is critical and weak. So, for this reason, and to prevent structure failure at this point, we overlap the reinforcement to ensure that there is sufficient length to transfer stresses at this point, which prevent: tension, pull-out, and shear failure at the location of joining the rebars. Figure no:1