Punching shear

Punching shear is a type of failure that occurs

on slabs due to high localized loads. In flat slab, this occurs at the columns

supports, as shown in figure no:1. The dead and live load of the slab will

generate a high shear force around the column's support. If the columns are not

well reinforced or the cross-section of columns is not big enough, the punching

shear will occur. We can see in figure no:2 that the columns support failed due

to punching shear, the columns in this figure seem to punch and penetrate the

slabs.

For two slabs supported by beams and wall, shear

calculated at a distance equal d from the face of beam or wall, usually the

shear is not a problem for this type of slabs. On the other hand, for flat

slabs where the slab is supported directly by columns, the shear is a critical

factor in the design. The designer should check one-way shear and punching shear.

The critical section for punching shear is taken at a distance of d/2 from the

face of columns or the drop panel. The shear strength usually equal to ɸλ

bwd.

The designer should consider punching shear

during the design stage. The punching shear design will involve the following

steps:

·

Checking if the concrete is strong enough to

resist punching shear

·

If no, we need to add sufficient reinforcement to

resist punching shear

·

Or we can increase the concrete thickness

around the columns and this can be done by introducing drop panels, increase

the slab thickness or increasing the column cross-section.

If the shear stresses are plentiful around the

interior column, shear resistance can be increased by using of shearheads.

Shearheads consist of four I or channel beams fabricated into a cross-arm then

placed above the support, as shown in figure no:3. ACI code

states that the shearheads can’t be used to increase the shear resistance for

exterior columns. Therefore other methods shall be used for exterior columns.

Shearhead will increase the effective bo (perimeter

of the critical section for punching shear in slabs and footings) for the punching

shear. Also, it will increase the negative moment resistance for the slab. Another

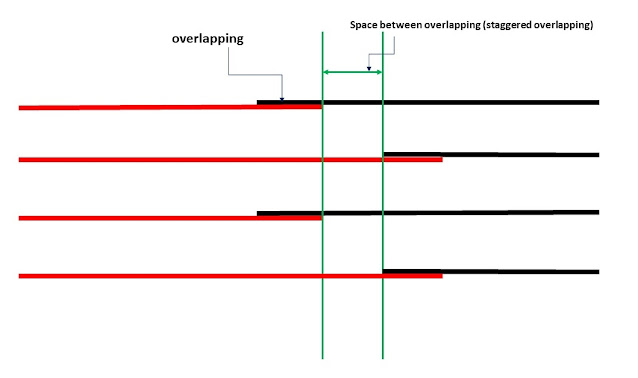

type of shear reinforcement is the using of a group of bent bars or wires, as shown in figure no:4. The bars or wires are bent at 45˚ across the potential punching crack zone. The bent bars are extended at the bottom of the slab to a length sufficient to fully

develop the bar strength.

The using of shearhead will push the critical

section of punching shear away from the column, as shown in figure no:5. Pushing the

critical section farther out from the column will increase the area and provide

a larger perimeter to resist the shear.

According to ACI318-14[22.6.9.8], the critical section of the shear will

cross the shearhead arm at a distance from the column face

3/4*(lv-(c1/2))

Where

lv is the length of the shearhead arm from the centroid of the concentrated

load or reaction

c1 is the dimension of the rectangular or

equivalent rectangular column or capital or bracket, measured in the direction

in which moments are being calculated.

Figure 5

Comments

Post a Comment