cracking of concrete

Concrete crack is very common, and it can occur due to various reasons. The depth and the width of the crack will determine the severity of cracks on concrete members. Shortly after placing and compacting the concrete, the concrete will undergoes a shrinkage. Shrinkage can be defined as a reduction of size due to losing concrete moisture. The shrinkage will result in multidirectional drying shrinkage of concrete. The freshly placed concrete strength is lesser than the stress generated due to drying shrinkage, which results in concrete cracking. The shrinkage cracks are shallow, and it is seldom to extend down. Plastic shrinkage cracking occurs when the rate of evaporation of concrete moisture is high. The evaporation of concrete moisture will cause concrete shrinkage, while the concrete is plastic. The cracks generated by plastic shrinkage are deeper than drying shrinkage cracks, and the cracks form a parallel pattern, unlike drying shrinkage, which exhibits a circular pattern.

The changing of ambient temperature can be a source of concrete cracking. This type of cracks known as thermal cracking. The change of ambient temperature will cause the change of concrete member size, if expansion joints are not provided to accommodate the change of concrete member size, the member will crack and provide joints where needed. In bridges and buildings, special expansion joints are provided to accommodate the change of structure members because the size of these structures is big.

Differential settlement of structure can create tensile stress. Concrete has low tensile stress, and it ranges between 8-12% of compressive strength. Therefore, differential settlement can result in tensile stresses more than the resistance of, concrete which will cause concrete to crack.

Concrete cracking can occur due to other reasons such as the severe corrosion of steel rebar, alkali-aggregate reaction, freeze-thaw cycles, overloading, and many other reasons. Repairing of concrete cracks should start by determining if the crack is dead or live. cracks that open and close or widen progressively known as a live crack. Repairing of these cracks can be futile, the material used to repair these types of cracks will crack again, or the crack will form somewhere else. Therefore before starting with the repairing process, the size of cracks should be monitored by gauges to determine the type of crack. Dead crack can be repaired by epoxy resin injection. Epoxy resin can be used to structurally rebond the cracked concrete. If the purpose of repairing cracks is to seal the cracks and prevent water leakage, then polyurethane resin is more effective than epoxy resins.

Figure 1

The changing of ambient temperature can be a source of concrete cracking. This type of cracks known as thermal cracking. The change of ambient temperature will cause the change of concrete member size, if expansion joints are not provided to accommodate the change of concrete member size, the member will crack and provide joints where needed. In bridges and buildings, special expansion joints are provided to accommodate the change of structure members because the size of these structures is big.

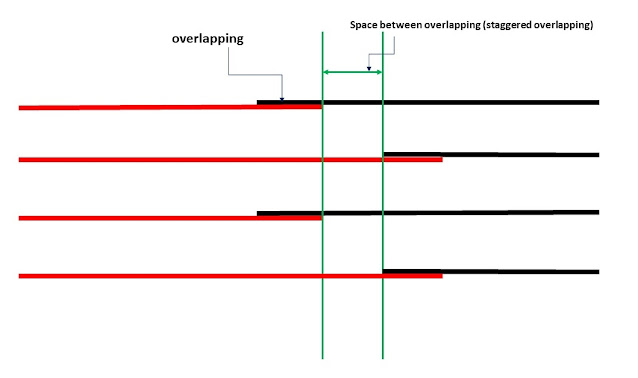

Figure 2

Differential settlement of structure can create tensile stress. Concrete has low tensile stress, and it ranges between 8-12% of compressive strength. Therefore, differential settlement can result in tensile stresses more than the resistance of, concrete which will cause concrete to crack.

Concrete cracking can occur due to other reasons such as the severe corrosion of steel rebar, alkali-aggregate reaction, freeze-thaw cycles, overloading, and many other reasons. Repairing of concrete cracks should start by determining if the crack is dead or live. cracks that open and close or widen progressively known as a live crack. Repairing of these cracks can be futile, the material used to repair these types of cracks will crack again, or the crack will form somewhere else. Therefore before starting with the repairing process, the size of cracks should be monitored by gauges to determine the type of crack. Dead crack can be repaired by epoxy resin injection. Epoxy resin can be used to structurally rebond the cracked concrete. If the purpose of repairing cracks is to seal the cracks and prevent water leakage, then polyurethane resin is more effective than epoxy resins.

Figure 3 (crack gauge)

The article is extremely beneficial , personally I loved the points that are mentioned in the article. We would like to introduce ourself as the oldest and leading supplier of structural steel products from West Bengal , Kolkata, India. To know more about us , you can simply google Shree Ji Steel Corporation on the search box. This is our company name, we are serving our clients with best quality of steel products from generations.

ReplyDeleteHere are some products that we offer to our clientele :

Wholesale Supplier of Iron and Steel Products

Wholesale Supplier of Mild Steel TMT Bars

Wholesale Supplier of Mild Steel Angles

Wholesale Supplier of Mild Steel Channels

Wholesale Supplier of Mild Steel Beams

Wholesale Supplier of Mild Steel Plates

Wholesale Supplier of Mild Steel Flat Bar

Wholesale Supplier of Mild Steel Round Bar

Wholesale Supplier of Mild Steel Square Bar

Wholesale Supplier of Mild Steel Wire Rod

Wholesale Supplier of Mild Steel Binding Wire

Wow :)

ReplyDeleteThis is an incredible collection of ideas!

Waiting for more helpful pieces.

You would amazing to read a similar one here-

besttoolsbrand