concrete workability

concrete workability is a property of concrete determining the ease of mixing, placing and compacting concrete with minimum loss of homogeneity.

Factors affecting workability

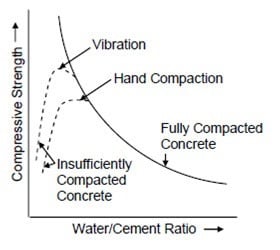

- W/C: increasing of water-cement ratio will increase concrete workability but it will reduce the strength of the concrete mix. increasing water-cement ration will increase concrete permeability and this will reduce concrete strength and durability. on the other hand, using concrete with little water insufficient to interact with cement particle to cause hydration this will result in strength reduction. W/C usually ranges from 0.35-0.40.

- size of aggregate: Bigger size of aggregate means lesser surface area. as a result, the amount of water required for wetting the aggregate surface is lesser than the smaller size.and this will result in higher workability for the same water content.

- the shape of aggregate: aggregate with elongated flaky shapes will reduce the workability of concrete compared to round or cubical aggregate.

- Grading of aggregate: well-graded aggregate will enhance concrete mix workability. when the voids are reduced, extra paste will be available to give better lubricating effects.

- using of admixture: adding of admixture such as superplasticizers helps in increasing concrete mix workability and reduce W/C.

Measuring concrete workability

concrete workability can be measured using one of these tests:

- slump test

- Compacting Factor Test

- Flow Table Test

- VeBe Test

- Kelly Ball Test

adding water to increase concrete workability at the field(for ready-mix concrete) is highly prohibited because it will increase concrete permeability and this will reduce strength and durability of concrete.

Comments

Post a Comment