Working piles (cast in situ piles)

Various Methods Used in Constructing

Cast In-Situ Piles

The general concept of cast in-situ

pile construction remains the same across various methods, with minor

differences. Bored pile diameters typically range from 600 mm to 3000 mm, with

depths reaching up to 70 m. This provides designers with significant

flexibility to customize foundation designs according to site conditions and

optimize costs for an economical solution.

Casing

Installation

The depth of casing varies based on

site conditions and soil properties. In the presence of loose soil, the casing

length should be increased. The use of bentonite can help prevent soil

collapse, reducing the required casing length.

The primary function of the casing

is to prevent soil collapse in loose soil conditions or when soil-supporting

liquids are absent. It also allows land surveyors to verify pile locations and

provides guidance for drilling machines. Casing installation involves drilling

a shallow hole with the same diameter as the casing to facilitate insertion

using a vibration hammer.

The casing diameter should be slightly larger than the pile diameter and free from distortion. For long casings, joints must be properly and smoothly welded. Before casing installation, any residual or encrusted concrete must be removed.\

Setting Out

The casing location should be verified by a land surveyor and compared with the pile coordinates. The casing must be within 75 mm of the original pile location. If not, it must be lifted and repositioned.

Boring

Boring should commence only after verifying the casing location. Drilling is performed using a rotary rig or other suitable equipment. The drilled shaft depth must be at least equal to the pile depth, calculated as follows

Depth of Drilling = Casing Top Level - Toe Level

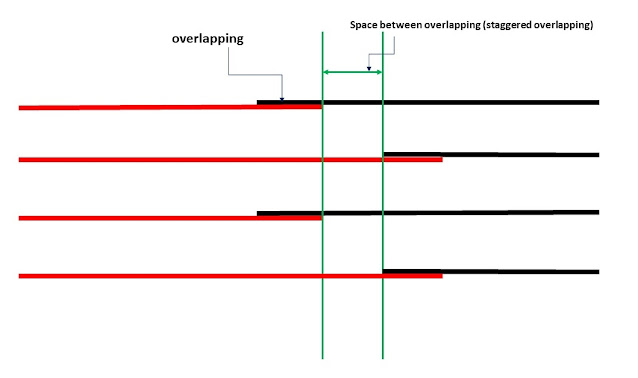

Steel Cage Fabrication and LoweringThe steel cage should be fabricated as per the design drawings. The steel must be free from rust, and any rust formation should be thoroughly removed. Concrete cover blocks should be used to maintain the required cover, with the concrete strength of the cover blocks matching that of the pile to prevent spalling or deterioration.

PVC sleeves can be used to confine steel projecting above the cut-off level, facilitating easier concrete breaking in later stages. Overlap length and location must comply with the design specifications.

Pile

Casting

To avoid soil sedimentation, the time between lowering the steel cage and pile casting should be minimized. Tremie pipes must be used for pile concreting and should be free from residual concrete, oil, grease, or any contaminants. The tremie length should be at least equal to the borehole depth. During casting, the tremie must remain embedded in the concrete at all times to prevent segregation or contamination.

Casing

Removal

The casing should be removed while

the concrete is still fresh. Delayed removal can cause adverse effects, such as

concrete cracks or adhesion between the concrete and the casing, leading to

potential pile extraction during casing removal. If casing removal is

significantly delayed, it is advisable to leave the casing in place and conduct

a static compression test to verify pile capacity.

Use

of Stabilizing Liquids

Property

|

At

time of slurry

Introduction

|

In

hole at time of

concreting

|

Test

method

|

Density

|

995-1018kg/m3

(Fresh

water)

|

1000-1018kg/m3

(Fresh

water)

|

Mud

Balance

(API

13B-sec1)

|

Viscosity

(minimum)

|

45sec/.95liter

|

45sec/.95liter

|

Marshal

funnel

|

PH

|

8-10

|

8-10

|

pH

paper/pH meter

(API

13B-Sec6)

|

MAX

sand content

(1%

by volume)

|

1

|

1

|

Sand

Screen set

(API

13B-Sec4)

|

Limitations

of Cast In-Situ Piles

Minimum

Clearance

Adequate clearance must be

maintained between adjacent cast in-situ piles during construction. The minimum

distance should be at least three times the pile diameter. If a smaller

clearance is unavoidable, one pile should be bored and cast first, and the

adjacent pile should only be drilled and cast after allowing sufficient curing

time (typically seven days).

Tremie

Pipe Considerations

The internal diameter of the tremie

pipe should be at least 150 mm for a concrete mix with a maximum aggregate size

of 20 mm. This ensures a smooth concrete flow. For small-diameter piles, the

tremie pipe size must be selected carefully to avoid difficulties during

insertion. Additionally, any attachments to the steel cage, such as sonic tubes,

must be considered during planning.

Comments

Post a Comment