Allowable stress and allowable load

Designing a structure required a good knowledge of materials strength and load capacity. the required load to be supported or transfer by structure shall be less than the structure capacity. if the structure subjected to a load larger than it is capacity it will fail. therefore the actual strength of structure shall exceed the required strength. the ratio of the actual strength of the structure to required strength is known as the factor of safety.

the factor of safety shall be reasonable. a very low factor of safety means a high likelihood of failure. if the factor of safety is very high this means a large and uneconomical structure with a great waste of materials. because of difficulties and different factors involved in the structure design. the factor of safety determined on a probabilistic basis. the determination of factor safety will involve the cooperation of experienced engineers who write codes and specifications

Ƞ=ِAcutual strength/required strength

the factor of safety shall be higher than one. the factor of safety magnitude can range from slightly above 1 to 10 or more. Determining the magnitude of the factor of safety is difficult because strength and failure have a different meaning. actual strength of the material is the load and stress capacity of a structure. failure of a structure may mean the total collapse of the structure. or it could mean the excessive deformation of the structure. required load for the second case will be less than the total collapse and this required a higher factor of safety. determination factor of safety dependents on:

- the possibility of accidental overloading greater than the design loads

- types of load (static and dynamic)

- load cycle and the possibility of fatigue failure

- workmanship and inaccuracies of construction

- surrounding environment

- importance of the structure

- other consideration

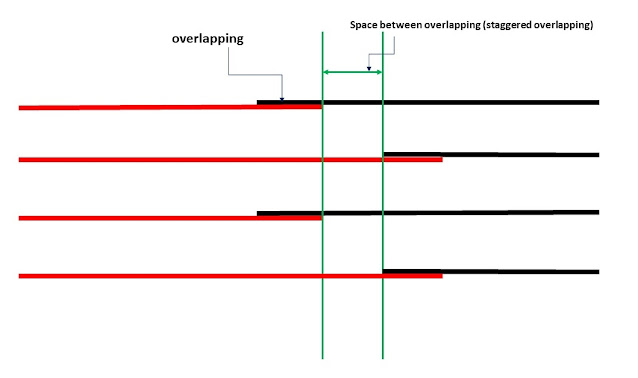

Figure 1

in the aircraft industry, it is customary to speak about the margin of safety

margin of safety =Ƞ-1

allowable stresses

the factor of safety dependants on different factors. for some materials, it is required that the loads and stresses remain with the elastic region. so materials will not undergo permanent deformation. allowable stress can be calculated for this case

allowable stresses=Yield strength/factor of safety

for tension and shear

σa=σy/Ƞ1, τa=τy/Ƞ2

for some materials factor of safety applied to ultimate strength. this used usually for brittle materials such as wood and plastic were no clear yield point.

σa=σu/Ƞ3, τa=τu/Ƞ4

the factor of safety for ultimate strength usually higher than the factor of safety for yield strength.

allowable loads

allowable loads shall be calculated as follows

Allowable load=(allowable stress)(Area)

for bars in direct tension or compression

Pa=σaA

where σa is the allowable stress in tension or compression and A is the cross-section area

for direct shear

Pa=τaA

where τa is the allowable shear stress and A is the area where shear stress acts.

Comments

Post a Comment