Changes in length of axially loaded members

Length of axially loaded members will change when they are subjected to axial load, members length will decrease when it is subjected to compression load, The length will increase for tension loads. to illustrate the concept we will begin with spring.

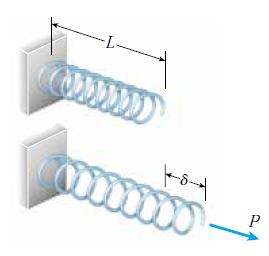

Let consider spring in figure 1, assuming that this spring is subjected to tension force equal P, the length of spring before elongation equal to L. after applying the force the length will increase by δ, the total length after elongation will be L+δ. if the material is linearly elastic the load and elongation will be proportional

Let consider spring in figure 1, assuming that this spring is subjected to tension force equal P, the length of spring before elongation equal to L. after applying the force the length will increase by δ, the total length after elongation will be L+δ. if the material is linearly elastic the load and elongation will be proportional

P=k*δ, δ=f*P

The constant k is the stiffness of the spring and can be defined as the force required to make a unit of elongation. the constant f is the flexibility of the spring and can be defined as the elongation produced by a load of unit value.

k=P/δ, f=δ/P

k=1/f, f=1/k

flexibility can be determined easily by measuring the elongation for a known force, from flexibility stiffness of the spring can be calculated using the previous equation.

Figure 1

Prismatic bar, a prismatic bar will elongate under tension and shorten under compression similarly as in springs, if the prismatic bar cross-section is constant through the length with area A, prismatic bar could have different cross-section as shown in figure 2, if the load act at the center of bar, then stress will be σ=P/A, the strain ε=δ/L, assuming the material linearly elastic and using hook law σ=E*ε, where E is the modulus of elasticity, elongation can be calculated using the following equation after rearranging hook's law

δ=P*L/(A*E)

The elongation is directly proportional to P and L, and inversely proportional to A and E, the product of A*E is known as axial rigidity.

Figure 2

The stiffness and elongation for bar defined similarly as in spring, stiffness is the force required to produce a unit of elongation K=(AE)/L, flexibility know as the elongation generated from applying a load of unit value f=L/(AE)

Cables, cables are similar to bar and spring when they are subjected to tensile force, cables cannot resist compressive force and they have a little resistance to bending, cables are made from strands wound around a central strand and each strand made from many wires wound helically. the cross-section area of a cable is the total cross-section area of individual wires and it is known as effective-cross section area, the effective cross-section area is less than the area of a circle with the same diameter due to space between wires of a cable.

for a cable with the effective area and material similar to a bar, the elongation of cable will be more, because the wire will tighten up as in rope fibers, the modulus of elasticity for a cable known as effective modulus of elasticity is less than the modulus of elasticity for material which is made, the effective modulus of elasticity for a steel cable is around 140GPa (20,000Psi) while the modulus of elasticity for steel is around 210 GPa, 30,000Psi, the elongation for cable shall be calculated using effective cross-section area and effective modulus of elasticity.

Comments

Post a Comment