Minimum reinforcement of flexural members

Due to architectural or functional requirement, large dimensions for some members are selected, these members will have a large dimension compared to their bending requirement. therefore, a light amount of reinforcement will be sufficient to resist the service loads and moments.

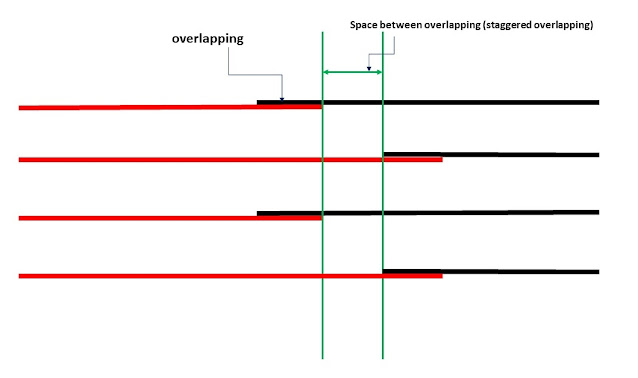

Figure 1

for members with very light reinforcement, the ultimate resisting moment will be less than their cracking moments.

Mcr=(fr*I/y)

where

Mcr is the cracking moment.

fr is the modulus of rupture

I is the moment of inertia

y is the distance from neutral axis to extreme compression fiber

a smaller area of steel means a smaller nominal flexural strength of the member. on the other hand, large dimension means a larger moment of inertia and this will increase the cracking moment magnitude. if this member cracks it will fail suddenly and it will jeopardize the whole structure.

Mn=As.fy(d-a/2)

where

Mn is the nominal flexural moment

As is area of steel

d is the effective depth of member

a is the depth of Whitney compression block

ACI [10.5.1] specifying the minimum area of steel required

for SI units

As,min=(0.25√fc'/fy)*bw*d and not less than 1.4bw*d/fy

For us units

As,min=(3√fc'/fy)*bw*d and not less than 200bw*d/fy

ACI[10.5.2] stating that bw shall be substituted with 2*bw or the flange width whichever is smaller for a statically determined member where the tension reinforcing steel is in the flange

Figure 2

we can rewrite the previous equation using ρ=As/(b*d)

for SI units

ρmin=(0.25√fc'/fy) and not less than 1.4/fy

For us units

ρmin=(3√fc'/fy) and not less than 200/fy

Comments

Post a Comment