Analysis of T Beams

Analysis of T beam is similar to rectangular beam. same equations will be used if 'a' is less than the depth of flange hf. "a" is the depth of compression block. if "a" is larger than hf. compression stress will be distribuated over flange and web. flange and web has different width. therefore the compressive force C=0.85*fc'*hf*bf+0.85*fc'*(a-hf)*bw as shown in figure 1.

Example: Compute nominal moment for the T beam shown in Figure 2, in which fc' = 4000 psi and fy = 60,000 psi.

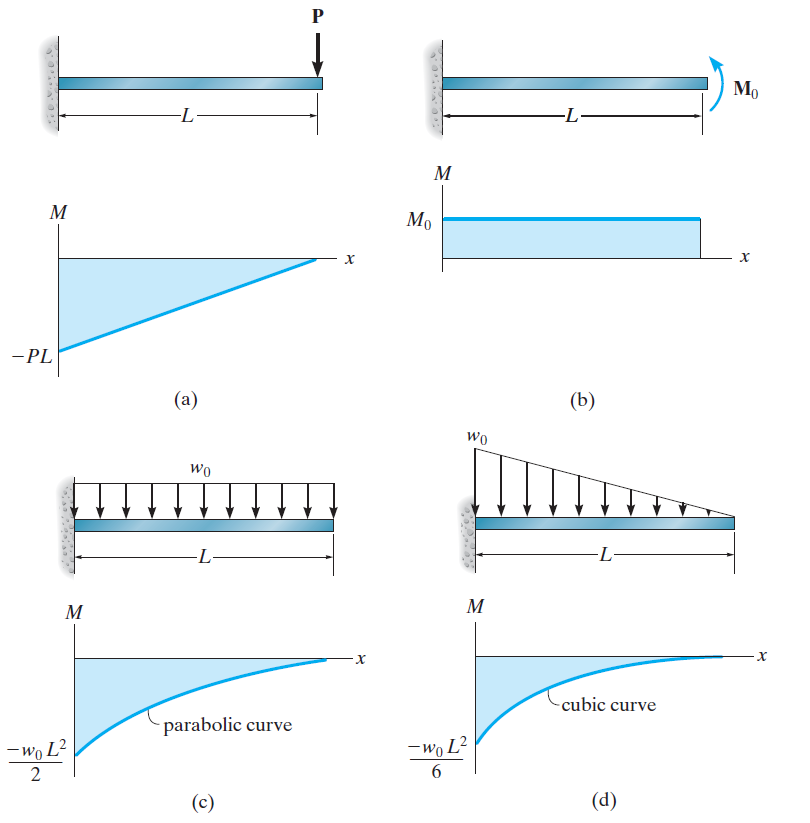

Figure 1

the procedure of analyzing of T Beams

- Compute T=As*fy

- determining if a > or < hf by calculating AC=T/0.85*fc', if AC>Area of flange(hf*bf) then a is more than hf

if a<hf

As*fy=0.85*fc'*a*bf

a=(As*fy)/(0.85*fc'*bf)

if a>hf

AC=AC by flange +AC by web

AC by web=(AC-AC by flange)

bw*(a-hf)=(AC-AC by flange)

a=(AC-AC by flange)/(bw)+hf

AC by flange=0.85*fc'*hf*bf

for this case we need to determine the center of gravity of the concrete block

center of gravity from a reference point (y)=(moment of area from the refence point)/(area of concrete block)

- calculate εt to determine Ф

- calculate Ф*Mn=Ф*As*fy(d-a/2)

Figure 2

T=As*fy=10.12*60,000=607,200lb

Ac=T/0.85*fc'

AC=178.58 in2

A of flange=30*4=120 in2

AC>Af the compression block will extend below flange

a=(AC-AC by flange)/(bw)+hf

a=(178.58-4*30)/(14)+4=8.18in

neutral axis(from top fiber) of compression block=(0.85*4000*4*30*2+0.85*4000*14*4.18*6.09)/(0.85*4000*4*30+0.85*4000*14*4.18)

y=3.34 in from top

Mn=As.fy*(d-y)

where d-y is the vertical distance between the center of compression force and tension force(moment arm)

Mn=607,200*(30-3.34)=16,187,952 lb-in=1,349 k-ft

Figure 3

This article measurement is very informative & helpful for gasket users and ginseal spiral wound gasket manufacturer also.Metal spiral wound gasket is used with the flanges by oil industries to avoid the leakage of flange joints or pipes.it is very useful tools for machinery industries.

ReplyDeleteLooking for casting parts in automobile ? Then we are the best for you, who suit your expectations. We have huge experience on this field. We are 100% dedicated to find you cheap casting parts in automobile.

ReplyDeleteYou can buy casting parts in automobile safely here and here are numberius clients buy casting parts in automobile. We are provide only high perfomence machine only with always customers support.

If you want to know more, Please check out here : casting parts in automobile

This essay has wonderful information. Additional details regarding the business that are found on the rexton alloys website High Tensile Sailma 450 Sheet Manufacturer .

ReplyDeleteThis essay has excellent information. On the website Rexton Alloys, there are more specifics about the company products Alloy 28 Sheet & Plate.

ReplyDeleteThis essay has useful info. On the Triton Alloys Inc website, you'll find additional information about the company JIS B 2220 5K Flanges .

ReplyDeleteVery informative and useful.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteFalse ceiling boards are an ideal choice for enhancing interiors with a modern and elegant look. Made from high-quality materials like gypsum, POP, or fiber, they provide excellent insulation, fire resistance, and soundproofing. Easy to install and maintain, these boards are perfect for homes, offices, and commercial spaces. Available in various sizes and designs to suit every décor. Price range: ₹60 – ₹120 per sq. ft* (may vary based on material, design, and brand). false ceiling board price

ReplyDeleteCool

ReplyDelete