Repairing of active cracks

Cracks that are growing in size and depth over time are known as active crack. There are several methods used to repair cracks, but the reason behind the cracks should be investigated and removed. Overloading and thermal expansion or contraction could be a reason for developing a crack. Repairing of active cracks is insufficient without fixing the cause of the crack. In some cases, a new crack will develop near the old repaired crack.

These are the common methods for repairing cracks. To get rid of cracks, the reasons behind cracks should be eliminated. For example, if the cracks occur due to the expansion of the structure, expansion joint should be installed to allow for structure movement and to release stresses. Flexural cracks will develop if the structure is overloaded. For this case, the structure strength should be increased, and this could be done by external prestressing.

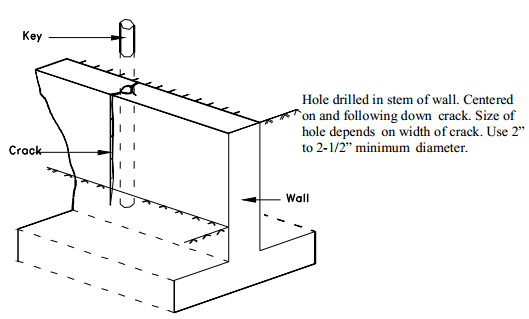

- Drilling and plugging through the crack: in this method, a hole is drilled near the crack, as shown in figure 1. this method suitable for straight-line cracks. The hole width and length should be equal or more than the crack width and length. Then the hole filled with grout. The grout forms a key that preventing the crack from growing and propagating. The diameter of the drilled hole range from 50 mm to 75 mm depends on the size of the crack. The hole can be filled with reinforcement and epoxy grout. The size of rebar should be predetermined and similar to crack size. If water tightness is primary need over structural load transfer, then the drilled hole can be filled by a resilient material of low modulus. If both properties are required, the first hole is filled with grout, and the second hole is filled with a resilient material.

Figure 1

- Stitching of cracks: in this method, holes are drilled on both sides of the crack, as shown in figure no:2. Then a U shape metallic staples are inserted and anchored in the holes. The length and orientation of the staples shall be variable to ensure proper distribution of the tension across the crack to concrete.

Figure 2

Figure 3

- External prestressing: external prestressing can be used to repair flexural cracks. External prestressing steel is anchored to the structure externally. Then the prestressing steel is tensioned. Prestressing steel will compress the concrete, and it will not allow for cracks to propagate. Also, it can be used to compensate for the loss of prestressing force in the existing tendons.

Figure 4

- Flexible sealing: in this method backup materials such as a closed-cell polyethylene foam sheet or rod is used to fill the crack as shown in figure 5. bond breaker will be used to prevent the adhesion of other materials.

Figure 5

These are the common methods for repairing cracks. To get rid of cracks, the reasons behind cracks should be eliminated. For example, if the cracks occur due to the expansion of the structure, expansion joint should be installed to allow for structure movement and to release stresses. Flexural cracks will develop if the structure is overloaded. For this case, the structure strength should be increased, and this could be done by external prestressing.

Excellent post and it is really useful for most of the freshers.

ReplyDeleteJapanese Classes in Chennai

learn Japanese in Chennai

German Courses in Chennai

Informatica MDM Training in Chennai

Hadoop Admin Training in Chennai

IoT Training in Chennai

Japanese Classes in Tnagar

Japanese Classes in OMR