What is water hammer?

Water hammer can be defined as a sudden increase of pressure inside the pipe due to the sudden change of direction or velocity of the liquid flowing inside the pipe. Water hammer can cause the rapture of the pipe and severe damage to the equipment.

To explain the cause of water hammer, we need to understand that the flowing liquid has two types of energies: Kinetic energy and potential energy. The kinetic energy generated by the velocity of the fluid while the potential energy represented by the liquid pressure. Neglecting the friction inside the pipe, the combination of both energy is constant along the pipe length. A sudden change of liquid velocity will result in changing the kinetic and potential energy. If the velocity decreased, the kinetic energy will decrease. The decrease of kinetic energy will result in an increase of potential energy or in other word, the pressure.

The water hammer occurred when the valve closed suddenly, and the flow of liquid stopped suddenly. The sudden closure of the valve will generate a shock wave that travels back and forth through the pipe of speed equal to sound velocity. The shock will continue until the liquid encounters a solid object such as a pump or a check valve. The shock wave will stop when the pressure is equalized.

Moreover, the sudden closing of the valve will exert forces on valve shut-off elements such as disc, ball, and gate. The pressure will increase on the upstream pipe side while it will decrease on pipe downstream. The liquid on the pipe downstream will attempt to continue the flow, which creates a huge vacuum on the valve downstream. The vacuum may cause the pipe to collapse or implode. Usually, air and vacuum valves installed in the downstream of the pipe to allow the air to enter and prevent the vacuum from occurring.

Water hammer can be caused by rapid pump start-up, rapid pump shutdown, movement of air pocket inside the pipe, and when the separated column rejoins at high velocity. The prevention of water hammer can be achieved by implementing the following control measures:

· Proper training for the staff on the danger of water hammer and how to avoid them through the proper opening and closing of the valve.

· Following the start-up and shut-down procedure for pumps to reduce the possibility of water hammer occurrence.

· Reduce the liquid velocity inside the pipe to keep the water hammer low.

· Using slow-closing valves such as gate valves.

· Using of air valves and pressure-relieving valves to mitigate the increase or decrease of pressure

· Use air chambers, surge vessels, accumulators, or expansion tanks that are partially filled with air or gas and cushion possible shock.

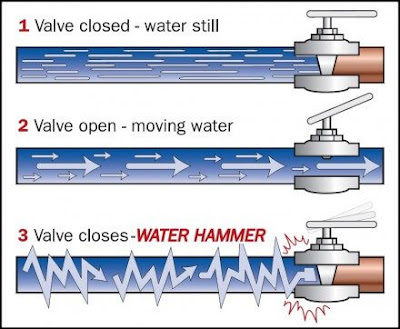

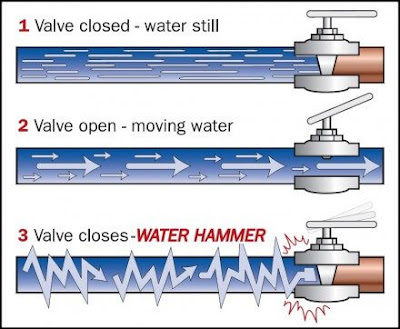

To explain the cause of water hammer, we need to understand that the flowing liquid has two types of energies: Kinetic energy and potential energy. The kinetic energy generated by the velocity of the fluid while the potential energy represented by the liquid pressure. Neglecting the friction inside the pipe, the combination of both energy is constant along the pipe length. A sudden change of liquid velocity will result in changing the kinetic and potential energy. If the velocity decreased, the kinetic energy will decrease. The decrease of kinetic energy will result in an increase of potential energy or in other word, the pressure.

The water hammer occurred when the valve closed suddenly, and the flow of liquid stopped suddenly. The sudden closure of the valve will generate a shock wave that travels back and forth through the pipe of speed equal to sound velocity. The shock will continue until the liquid encounters a solid object such as a pump or a check valve. The shock wave will stop when the pressure is equalized.

Figure 1

Moreover, the sudden closing of the valve will exert forces on valve shut-off elements such as disc, ball, and gate. The pressure will increase on the upstream pipe side while it will decrease on pipe downstream. The liquid on the pipe downstream will attempt to continue the flow, which creates a huge vacuum on the valve downstream. The vacuum may cause the pipe to collapse or implode. Usually, air and vacuum valves installed in the downstream of the pipe to allow the air to enter and prevent the vacuum from occurring.

Water hammer can be caused by rapid pump start-up, rapid pump shutdown, movement of air pocket inside the pipe, and when the separated column rejoins at high velocity. The prevention of water hammer can be achieved by implementing the following control measures:

· Proper training for the staff on the danger of water hammer and how to avoid them through the proper opening and closing of the valve.

· Following the start-up and shut-down procedure for pumps to reduce the possibility of water hammer occurrence.

· Reduce the liquid velocity inside the pipe to keep the water hammer low.

· Using slow-closing valves such as gate valves.

· Using of air valves and pressure-relieving valves to mitigate the increase or decrease of pressure

· Use air chambers, surge vessels, accumulators, or expansion tanks that are partially filled with air or gas and cushion possible shock.

Comments

Post a Comment