Concrete repair-selecting the repair method

Repairing concrete structure passes through various stages. Selecting the correct repair method will depend on completing the previous steps, such as determining the cause of concrete damage, evaluate the extent of the damage, and assess the need for repair. The completion of these steps will define the type of conditions the repair must resist, the available repair construction time period, and when repairs must be accomplished. The data collected from performing these steps will help in selecting which of the 15 standard methods is suitable and durable for repairing the damaged concrete structure.

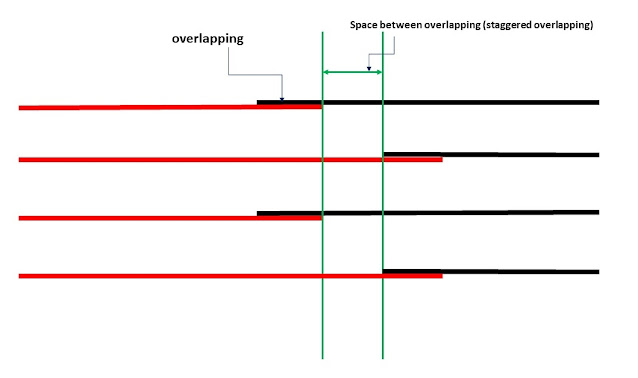

In general, the old concrete surface should be prepared before beginning with the repairing process. It is essential to remove all unsound concrete before applying the repairing. Improper preparing of damaged concrete structure will result in unsatisfactory repair with low durability. The first step in preparing the old concrete surface is the saw cutting of repairing area perimeters. The saw cut depth will range from 25-40 mm. The saw cutting of the repairing area perimeters aims to produce a retaining boundary to compact the repairing materials. Usually, the boundary of repairing area will be susceptible to shrinkage, bond failure, and deterioration. The saw cut in the concrete surface should be perpendicular to a concrete surface or tilted inward by 2 to 3 degrees to provide a retaining surface that will interlock the repairing materials into the area. Tilting the saw cut by more than 3 degrees can produce a weak top corner. The figure no:2 showing correct saw cut patterns. Saw cutting concrete at an acute angle, as shown in figure no:2, is incorrect, and it will complicate the compaction of repairing of material, which may impair the repairing of concrete.

Figure 1

Figure 2

Deteriorated concrete should be removed entirely to ensure the durable repairing of the damaged concrete structure. The removing of deteriorated concrete can be performed by high-pressure hydro blasting or hydro demolition. The using of this method will ensure the removal of unsound concrete while leaving the sound concrete on the place. Also, this method will not leave any microfracture surfaces on old concrete. Impact concrete removal techniques such as jackhammer and bush-hammering can also be used to remove deteriorated concrete surfaces. The using of this method can have some disadvantages, such as affecting the bond of reinforcement with surrounding concrete and surface micro fracturing. Pointed hammer bits, which are more likely to break the concrete cleanly rather than to pulverize it, should be used to reduce the occurrence of surface micro fracturing.

Reinforcement steel should also be prepared before applying the repairing materials. all rust, scaling, and corrosion must be removed by sandblasting, wire brushing, or high-water pressure. The preparing of reinforcement steel will ensure a strong bond between repairing material and the reinforcement. It is not necessary to clean the steel to white condition. The purpose of reinforcement steel preparation is to remove loose rust and debris. If the corrosion reduces the cross-section of reinforcement steel by more than 75% of the original diameter. The bar should be removed and replaced.

Once the repairing area is ready, we can apply the repair method. There are different 15 standard concrete methods such as surface grinding, Portland Cement Mortar, Dry Pack and Epoxy-Bonded Dry, aced Aggregate Concrete, shotcrete, replacement of concrete, Epoxy-Bonded Epoxy Mortar, polymer concrete, Thin Polymer Concrete Overlay, resin injection, High Molecular Weight Methacrylic Sealing Compound, Polymer Surface Impregnation, Silica Fume Concrete, and Alkyl-Alkoxy Siloxane Sealing Compound. Each of these materials has uniquely different requirements for a successful application. Proper curing of repairing area will ensure a durable concrete. Almost all repairing method requires appropriate curing. Improper curing can reduce the service life of the repairing methods.

Figure 3

Reinforcement steel should also be prepared before applying the repairing materials. all rust, scaling, and corrosion must be removed by sandblasting, wire brushing, or high-water pressure. The preparing of reinforcement steel will ensure a strong bond between repairing material and the reinforcement. It is not necessary to clean the steel to white condition. The purpose of reinforcement steel preparation is to remove loose rust and debris. If the corrosion reduces the cross-section of reinforcement steel by more than 75% of the original diameter. The bar should be removed and replaced.

Once the repairing area is ready, we can apply the repair method. There are different 15 standard concrete methods such as surface grinding, Portland Cement Mortar, Dry Pack and Epoxy-Bonded Dry, aced Aggregate Concrete, shotcrete, replacement of concrete, Epoxy-Bonded Epoxy Mortar, polymer concrete, Thin Polymer Concrete Overlay, resin injection, High Molecular Weight Methacrylic Sealing Compound, Polymer Surface Impregnation, Silica Fume Concrete, and Alkyl-Alkoxy Siloxane Sealing Compound. Each of these materials has uniquely different requirements for a successful application. Proper curing of repairing area will ensure a durable concrete. Almost all repairing method requires appropriate curing. Improper curing can reduce the service life of the repairing methods.

You have done a good job with your knowledge that makes our work easy because you are providing such good information. Keep sharing this kind of knowledge with us. concrete repair vancouver bc

ReplyDeleteYou have done a good job with your knowledge that makes our work easy because you are providing such good information. Keep sharing this kind of knowledge with us. Concrete company Calgary

ReplyDeleteA lot of valuable information can be derived from the post. Tricitiesengineering.com offers Foundation Design services and also provide quality, prompt and affordable services.concrete contractors tulsa, oklahoma

ReplyDeleteI am attracted by the presentation of this article. This information about Concrete is really good. I really appreciate your work. It is a gainful article for us. Keep posting. Thank you. commercial construction longview

ReplyDeleteIn this post you have shared such a great knowledge. I would like to thank you for sharing such an informative post. Keep Posting. San Antonio concrete

ReplyDeleteThis article provided me with a wealth of information. The article is both educational and helpful. Thank you for providing this information. Keep up the good work. Premier Restoration Services

ReplyDeleteThank you for providing me with such valuable information. This article provided me with some useful knowledge. Continue to make posts like this. Steel buildings Canada

ReplyDeleteYou've shared some incredibly useful information about Pile Driving Vancouver. This is frequently a terrific way for us to broaden our knowledge while remaining useful. Thank you for bringing this article to our attention.

ReplyDeleteYou've provided some very useful information. I'm glad I came into this article because it provides a lot of important information. Thank you for sharing this storey with us. bidwell concrete pavers for sale USA

ReplyDeleteI found decent information in your article. I am impressed with how nicely you described this subject, It is a gainful article for us. Thanks for share it. Automower

ReplyDeleteI'm sure you had great knowledge about this. You gave us much information. This information is really good and commentable about consulting engineers . Thanks for sharing your things with us.

ReplyDeleteLots of valuable data can be taken from your article about Boardwalk Systems. I am happy that you have shared great info with us, It is a gainful article for us. Thankful to you for sharing an article like this.

ReplyDeleteYou are giving such interesting information. It is great and beneficial info for us, I really enjoyed reading it. Thankful to you for sharing an article like this.New Driveways Lake District

ReplyDeleteExcellent post. I really enjoy reading and also appreciate your work.asphalt and paving contractors This concept is a good way to enhance knowledge. Keep sharing this kind of articles, Thank you.

ReplyDeleteI recently came upon your blog and wanted to express how much I liked reading your postings. I'm hoping you'll write again soon. Thank you very much for the excellent information. fence replacement services Longview WA

ReplyDeleteI'm blown away by the little print you've provided regarding signs. It is an enlightening article for both myself and others. Thank you for bringing such interesting topics to our attention. Concrete contractors San Antonio TX

ReplyDeletePost was pretty decent. I recently came upon your blog and wanted to let you know how much I've been enjoying reading your writings. I hope you will post soon again. Many thanks for the helpful information.Building inspector Perth

ReplyDeleteWonderful article and successful project , continue deliver post like these...Home Installer

ReplyDeleteDigital Satellite Installation

ReplyDeletethank u for the great article itys been a challenge to restore our surfaces at the Tar Paving Civils SA

ReplyDeleteYou have Shared great content here about clogged drain ToledoI am glad to discover this post as I found lots of valuable data in your article. Thanks for sharing an article like this.

ReplyDelete