Mechanical splicing of reinforcement steel

As we know, the reinforcement steel length is limited. For long structural members, the reinforcement steel bars should be overlapped or spliced to produce the required length of reinforcement. Mechanical splicing of reinforcement is used widely in the construction industry. Threaded couplers are a widespread type of mechanical splicing. Threaded couplers are sub-categorized into taper and parallel threaded couplers. The cross-section and length of the coupler will depend on the grade of the reinforcement rebar.

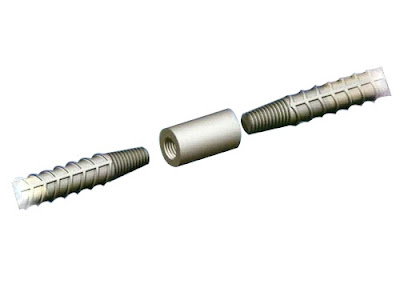

Taper threaded coupler is the simplest type of threaded coupler. This type of coupler can be used for columns and horizontal applications. But it is difficult to in rafts or other applications where it is difficult to turn and tighten the rebars. In general, the length of taper threaded couplers is more than parallel couplers. Taper threaded couplers are designed, taking into account defects of the rebar such as undersizing, skewness, and oblongness of the rebar.

Figure 1

Roll Threaded Couplers: roll threaded coupler is a type of parallel threaded coupler where the threads are formed by pressing the rebar end by a set of rollers. The end of the rebar should be cut vertically before threading as there is no allowance for additional threads inside the couplers. Tightening the rebar and coupler will require more turns due to parallel threads. This system will take more time for installation compared to the taper threading coupler system. This system can be used for vertical and horizontal applications such as columns and rafts.

Figure 2

Cold Forged Couplers/Upset Parallel Threaded Couplers: in this type of couplers, the end of rebars are enlarged by 10-30% by hydraulic pressure before cutting parallel threads on the enlarged rebar ends. This type of coupler is suitable for vertical and horizontal applications. The installation of cold-forged couplers will take a longer time compared to tapered threading coupler due to parallel threads. Used steel should possess sufficient ductility to prevent the formation of microcracks during the enlarging process of the end of rebars. Precautions that are needed for cold-forged couplers include ensuring that there is no play between the threads formed in this process and the coupler. Gauges are used to provide tolerance of the threads in such cases. It is vital.

Figure 3

Non-Threaded Couplers: There are various sub-types of non-threaded couplers, which are used mainly for the installation of couplers in location where it is not possible to use threaded couplers or for specialized applications. This category includes but is not limited to crimple/swage couplers, welded couplers, Bolted couplers, couplers with injected sleeves, friction-weld couplers.

Using mechanical splice can offer various advantages such as:

I like this article. I was searching over search engines and found your blog and its really helps thank you so much. get one of the best Cold Splicing Cement South Africa then visit on our website.

ReplyDelete