Waterstop for concrete structures

Large structures are usually poured in different stages. It is not possible to cast large structures at one time. The casting of large structures at one time will require a long time, a huge number of workers and equipment. In some cases, the geometric and sequence of work will require the casting of a structure in several stages. Pouring of concrete will result in forming construction joints between different concrete pours. Water-stop is usually used for various structures such as dams, water treatment facilities, storage tanks, culvert, slab on grade, and parking garage. The use of water-stop for storage tanks is critical. Water-stop will prevent the liquid from leaking. So, in general, water-stop will be used for structures that in direct contact with water. Water-stop will prevent the seepage of water from the construction joint. We have two types of water-stop. External water-stop fixed on the wet side of a concrete structure, as shown in figure no:2. External water-stop will prevent the ingress of mud and any other substances.

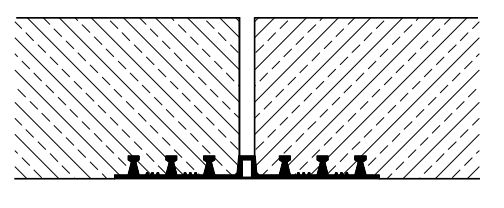

Figure no:2

The second type is internal water-stop. The internal water-stop will be fixed in the center of a concrete member. It will seal the member and prevent the passage of water through the joint. There are various types of internal water-stop. Ribbed flat and dumbbell water-stop used to seal the structures with no or little expected movement. Ribbed and flat with center bulb water-stop are another type of water-stop. These types of water-stop will be used for joints with expected movement. The center-bulb will accommodate the lateral and transverse movement. Aside from accommodating movement, these types of water-stop will prevent the passage of water as in other types of water-stop.

Figure no:3

Figure no:4

Comments

Post a Comment