Ductility of reinforcing steel

Ductility is an important property of steel reinforcement. Ductility is the ability of the material to undergo plastic deformation before failure. The ductility of reinforcement is related to the elongation property. The ductility of reinforcement ensures safer and durable structures. Material that undergoes little or no plastic deformation is known as a brittle material. Brittle reinforcement can cause sudden structure failure because it doesn't undergo any plastic deformation before failure.

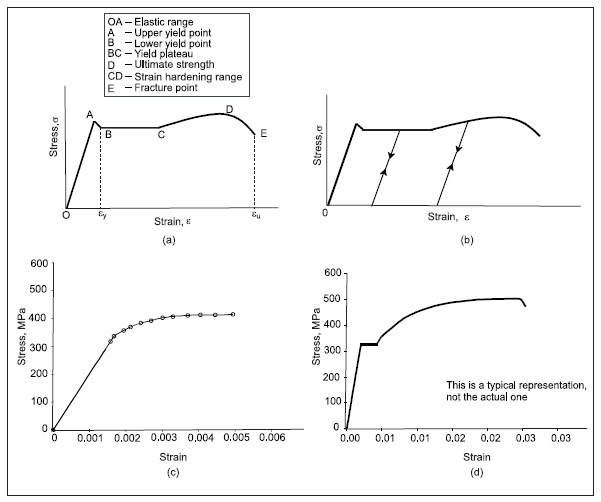

Figure 1

The ductility factor for reinforcement can be computed using the following equation:

µ=ϵu/ϵy

µ is the ductility factor

ϵu is the ultimate strain

ϵy is the yield strain

In figure no:1-a, we can see the stress-strain curve for mild steel. The mild steel has well-defined yield stress and strain, as shown in the stress-strain curve. The reinforcing bar can recover all the elongation if the applied stress is lesser than the yield stress. This portion of the curve is known as the elastic zone. If the applied stress is higher than the yield stress, the deformation will not recover fully after removing loads. The deformation beyond the yield strain is plastic deformation, and it can't be recovered after unloading the material. Figure no:1-b, showing the unloading stress-strain path for materials when the load is released. We can notice that the unloading stress-strain path is parallel to the original curve.

Similarly, the ductility factor can be calculated for CTD (cold twisted deformed) bars. Figure 1-c shows the stress-strain curve for the CTD bar. The yield strain(ϵy) for the CTD bar is the strain that corresponding to 0.2% proof stress. For a give value ϵy, the increase of ϵu means higher elongation, which means a higher ductility. The increase of gape between the yield strain (ϵy) and ultimate strain (ϵy) means higher plastic deformation, which means higher elongation and ductility. An example of this is reinforcement steel grade 500A, 500B, 500C. This reinforcement posses the same yield stress of 500 Mpa. But the ultimate stress for 500C>500B>500A and the min elongation is 3%, 5%, and 7.5% for 500A, 500B, and 500C respectively, which means that 500C will undergo a higher ultimate strain (ϵu), so it posses a higher ductility compared to 500B and 500A.

Another type of steel is prestressed steel. Prestressed steel is used in prestressed concrete. The prestressed steel possesses unique mechanical properties, which make it suitable for the use of prestressed concrete. The prestressed concrete is manufactured by tensioning prestressed steel. The tensioned steel then compresses the concrete. This process will enhance the concrete properties such as durability and ultimate capacity. Therefore, the prestressed steel should have a higher tensile strength. Prestressed steel grade270 has a yield stress of 1650 Mpa and ultimate stress of 1860 Mpa. the figure no:2 compares different types of steel. We can notice that the prestressed steel has a higher strength compared to other types of steel. But the ultimate strain for prestressed steel is lower than the grade 60 (yield stress=420Mpa). As a result, the ductility of prestressed steel is lower than mild steel.

Comments

Post a Comment