Manufacturing of Portland cement

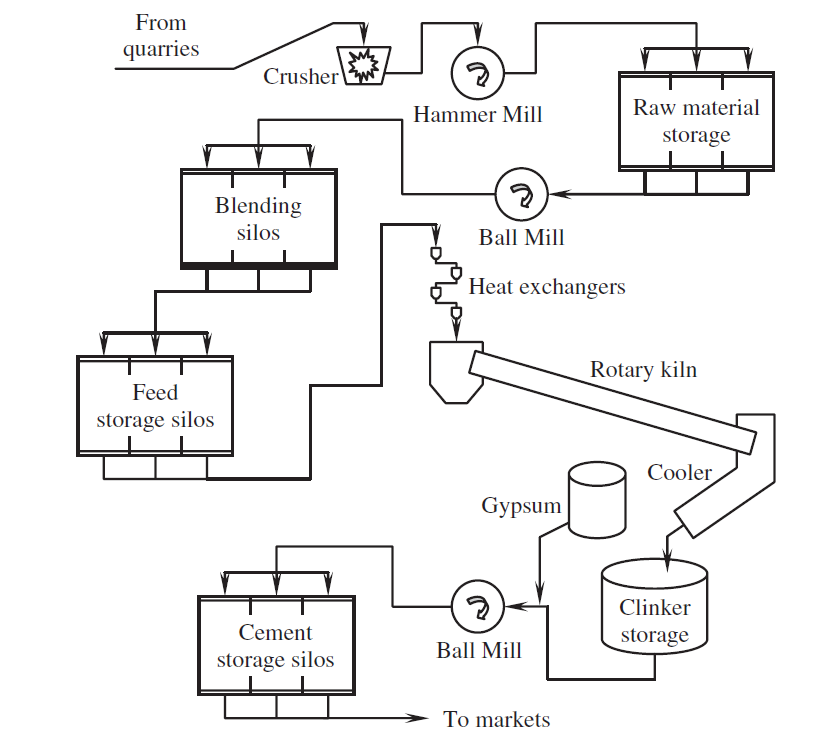

Portland cement is made by the mixing of limestone and clay or shale, then heating the mixture in a rotary kiln at a temperature of 1450 C. the materials supplied from quarries are crushed and blended into a uniform composition and fine size enough to enable the reaction at the rotary kiln. The heating of raw material will produce clinker. The clinker is grounded with gypsum to form the portland cement. Figure 1 showing the stages of manufacturing portland cement. The basic raw materials used to produce cement is limestone, clay, and iron ore. Figure 1 construction management: concrete construction bridge construction:How to become a bridge engineer The chemical composition of cement: Major compounds: major compounds of portland cement is listed in table number 1. C2S and C3S occupy 68% to 75% of portland cement. Since the primary constituents of Portland cement are calcium silicates, we can define Portland cement as a material that