Design of bridge pier

The structural member is subdivided into two regions. Region B (BERNOULLI), where the beam theory assumptions are applicable. The main assumptions of beam theory are the cross-section of beam do not deform significantly under applied load, and beam cross-section remains planner and normal to deform axis of the beam. On the other hand, Portions of a structure where the beam theory is not applicable classified as region D. discontinuity, change in section dimension, opening, nodes and connection of girders and beams are examples of D-region.

Members with vary cross-section such as pier cap can be designed using strut and tie method. Strut and tie method is suitable for designing members where beam theory is not applicable. Moreover, it is a conservative method and can be used for the B region. The main concept of the STM method is to represent the flow of internal forces using a truss system consist of strut, ties, and nodes. The modeling of strut and tie is a bit challenging and can vary depends on engineer evaluation and judgment.

Strut and tie method for pier cap

For hammer pier, the cross section of pier change suddenly. This geometric discontinuity will cause a non-linear distribution of strain. Therefore, it is preferred to use STM to design the pier cap. The using of beam theory is not appropriate and can cause discrepancies.

STM modeling

Strut and tie model will be established for a structural member under investigation. The process of modeling can be repeated several times until achieving acceptable geometry of truss and verifying sizes of truss member.

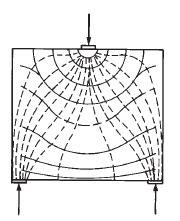

The selection of strut and tie location shall represent the realistic stresses flow from the load to the supports. For figure no:1, the dashed lines represent compression stress trajectories, and the solid lines represent the tension stress trajectories. The representation of these stress identified in figure no:2 the internal compression stress represented by strut (dashed line) and the tension stresses by tie (solid line). In addition to internal stress, the locating of ties should take into consideration the layout and practicality of placing reinforcement steel for a structural member.

|

| Figure 1 |

|

| Figure 2 |

The axis of strut shall be located at a distance of a/2 from the edge of the beam in the compression zone. Where a is the depth of a rectangular stress block. Similarly, the ties shall be placed at a distance of a/2 from the edge of the beam in the tension zone.

Figure no:3 showing a strut and tie model for a hammer pier cap. We will analysis the configuration and summarize the points that can assist in designing the STM model.

|

| Figure 3 |

1. Place the nodes below the loading point and nodes for the reaction at the column. In figure no:3 nodes will be A, C, E, G, I, M, and L.

2. In designing the STM model. The priority should be given for locating strut members. The load will be transferred to the reaction point if the angle with vertical is less than 60 º. In our case, the angle from A to M is more than 60º, so strut cannot be drawn from A to M.

3. The load shall be transferred to a point below bearing location if the angel with vertical between 30º and 60º. In our case, the angle ϕ from A to N is more than 60º, so a new node added at O.

4. For new nodes such as B, the load will be transferred at angle ϕ of 45º approximately. The equilibrium should always be maintained, so a new tie OB is added for node B.

5. Same rules shall be applied for node O. For strut O-M the angles with vertical are more than 60º, so the first rule didn’t apply. Therefore, the load will be transferred to point N. the second rule will be used.

Once the STM modeling completed. The forces for each member of truss shall be calculated. Based on calculated forces, the amount of steel will be calculated. Moreover, the capacity of the strut will be verified.

Design of compression strut

The area of concrete strut should be calculated to determine the nominal resistance of compressive strut. The area of the concrete strut will be controlled by the available concrete area and anchorage condition.

When strut anchored by steel reinforcement. The effective area may be extended to a distance of 6dba beyond anchoring steel where dba is the diameter of anchoring bar. Figure no:4 illustrates the concept of calculating the effective concrete area for the anchored strut.

|

| Figure 4 |

Figure no:5. Depicting a strut anchored to bearing and tensile reinforcement. For similar condition, the width of the strut can be calculated as shown in the figure.

|

| Figure 5 |

Calculating the width of strut anchored to bearing plate and other strut represented in the figure no:6

|

| Figure 6 |

The nominal compressive resistance of strut can be calculated using the following equation [AASHTO 5.6.3.3.1].

Where

Acs is the effective cross-section of a compressive strut.

fcu is limiting compressive stress and can be calculated using the following equation

fcu=fc'/(0.8+170ε1)

ε1=(εs+0.002)*(cot αs)^2

where

fc’ is the concrete compressive strength.

εs is the strain of steel passing through the concrete strut

αs is the smallest angle between concrete strut and tensile tie.

Pu for a strut member shall be always less the ϕPn. Where ϕ is a reduction factor equal to 0.7 for compression members [AASHTO 5.5.4.2.1].

Design of tension tie

The reinforcement for tie should be embedded in the nodal zone by a specified embedment length. AASHTO 5.11 specified the requirement for development length. The nominal resistance of tensile tie should be calculated using the following equation [AASHTO 5.6.3.4.1].

Pn=fyAst+Aps[fpe+fs]

Where

fy is the yield strength of longitudinal mild steel for a tie(MPA).

Ast is the total area for longitudinal mild steel for the tie(mm2).

Aps is the area for prestressing steel.

fpe is the effective prestressing force.

ϕPn for tie should be more than Pu (ultimate tensile force at tie). Φ is equal to 0.9, according to AASHTO LRFD. Therefore, a sufficient amount of Ast shall be provided to surpass the ultimate force on the tie.

Vertical ties such as OB and CN should be used to determine shear reinforcement. Number of stirrups can be calculated using the following equation

n=Ast/Astirrup

Two legs or four legs stirrups can be used. The stirrups for OB shall be distributed evenly at L2. Spacing between stirrups can be calculated using the following equation.

S=L2/n

Where

S is the maximum spacing between stirrups.

L2 is the length of the stirrups region.

n is the number of stirrups to comply with Ast.

Design of nodes

AASHTO LRFD limiting the compressive stress at node region according to node region configuration. The limitation can be categorized into:

1. Compressive stress should be less than 0.85 ϕfc’ for nodes with a strut and bearing area.

2. Compressive stress should be less than 0.75 ϕfc’ for nodes with tension tie in one-direction only.

3. Compressive stress should be less than 0.65 ϕfc’ for nodes with tension tie in more than one direction.

There stress in the nodal zone can be reduced by increasing bearing area, strut area, and tie area. In the events of using prestressing for the concrete member. And the stress in the concrete didn’t exceed the effective prestressing force. The limiting compressive stress should be taken as 0.85 ϕfc’ because the nodal zone didn’t experience any tensile strain.

Pier column design

Column transfers axial loads and resists lateral load imposed on superstructure and column. Shapes of the column section can differ from circular, rectangular, octagonal and others. Slenderness defined as the tendency of the column to buckle. Columns are divided into slender column (tall) and stock column (short).

Columns slenderness

Columns slenderness is an essential factor. The design approach varies depends on the slenderness of columns. Slenderness effects can be evaluated by calculating the slenderness ratio.

S=(K.lu)/r

Where

K is the effective length factor.

lu is the unsupported length of the compression member

r is the radius of gyration

According to AASHTO 5.7.4.3 if the slenderness ration is more than:

S=(K.lu)/r≤22

S=(K.lu)/r≤34-12 M1/M2for members braced against sway.

Where

M1 is the smaller end moment.

M2 is the larger end moment.

If the slenderness ration is more than the above values and less than 100. Moment shall be magnified according to AASHTO 4.5.3.2.2b.

According to AASHTO, the factored axial resistance for compression member subjected to pure compression can be calculated using the following equation.

1.For a member with spiral reinforcement

Pn=0.85ϕfc'(Ag-Ast)+fy.Ast

2.For a member with tie reinforcement

Pn=0.80ϕfc' (Ag-Ast)+fy.Ast

Where

Φ is the resistance factor in AASHTO 5.5.4.2

fc’ is the concrete strength at 28 days

Ag is the cross-section area for compression member (mm2)

Ast is the area of longitudinal reinforcement(mm2)

fy is the yield stress of reinforcement steel(MPA)

Reduced nominal compression resistance should always be larger than applied ultimate load

ϕPn≥Pu

Biaxial flexural

It is rare for a column to be loaded with pure compression only with no bending moment. The bending moment can be generated due to continuity in structure spans. Transverse loads, temperature change, concrete shrinkage, and creep will induce bending stresses on columns. According to AASHTO5.7.4.5, the axial resistance can be calculated for column subjected to axial load with eccentricity in both direction and axial load with bending moment using the following equation.

If factored axial load Pu≥0.1ϕfc' Ag

1/Prxy=1/Prx+1/Pry-1/ϕPo

Where

Po=0.85fc' (Ag-Ast)+fyAst

If factored load Pu>0.1ϕfc'Ag

Mux/Mrx+Muy/Mry≤1

Where

Prxy is factored axial resistance in biaxial flexure.

Prx is factored axial resistance based on the assumption of ey is present only

Pry is factored axial resistance based on the assumption of ex is present only

Pu is factored applied axial load.

Mux is factored applied moment about the x-axis

Muy is factored applied moment about the y-axis

Mrx = uniaxial factored flexural resistance of a section about x-axis corresponding to the eccentricity produced by the applied factored axial load and moment.

Mry = uniaxial factored flexural resistance of a section about y-axis corresponding to the eccentricity produced by the applied

factored axial load and moment

The uniaxial resistance (Prx,Pry,Mrx,Mry) can be calculated using the column design chart. Column design charts as in figure no:7 will help in reducing time and simplifying the complexity of designing biaxial flexural column. Uniaxial resistance will be calculated for each direction then used in the previous equation to calculate biaxial resistance of the column.

1.For a member with spiral reinforcement

Pn=0.85ϕfc'(Ag-Ast)+fy.Ast

2.For a member with tie reinforcement

Pn=0.80ϕfc' (Ag-Ast)+fy.Ast

Where

Φ is the resistance factor in AASHTO 5.5.4.2

fc’ is the concrete strength at 28 days

Ag is the cross-section area for compression member (mm2)

Ast is the area of longitudinal reinforcement(mm2)

fy is the yield stress of reinforcement steel(MPA)

Reduced nominal compression resistance should always be larger than applied ultimate load

ϕPn≥Pu

Biaxial flexural

It is rare for a column to be loaded with pure compression only with no bending moment. The bending moment can be generated due to continuity in structure spans. Transverse loads, temperature change, concrete shrinkage, and creep will induce bending stresses on columns. According to AASHTO5.7.4.5, the axial resistance can be calculated for column subjected to axial load with eccentricity in both direction and axial load with bending moment using the following equation.

If factored axial load Pu≥0.1ϕfc' Ag

1/Prxy=1/Prx+1/Pry-1/ϕPo

Where

Po=0.85fc' (Ag-Ast)+fyAst

If factored load Pu>0.1ϕfc'Ag

Where

Prxy is factored axial resistance in biaxial flexure.

Prx is factored axial resistance based on the assumption of ey is present only

Pry is factored axial resistance based on the assumption of ex is present only

Pu is factored applied axial load.

Mux is factored applied moment about the x-axis

Muy is factored applied moment about the y-axis

Mrx = uniaxial factored flexural resistance of a section about x-axis corresponding to the eccentricity produced by the applied factored axial load and moment.

Mry = uniaxial factored flexural resistance of a section about y-axis corresponding to the eccentricity produced by the applied

factored axial load and moment

The uniaxial resistance (Prx,Pry,Mrx,Mry) can be calculated using the column design chart. Column design charts as in figure no:7 will help in reducing time and simplifying the complexity of designing biaxial flexural column. Uniaxial resistance will be calculated for each direction then used in the previous equation to calculate biaxial resistance of the column.

|

| Figure 7 |

Comments

Post a Comment