Shotcrete concrete

Shotcrete concrete can be defined as a mixture of cement, aggregate and water sprayed pneumatically through a nozzle and at a high velocity to produce a compacted, dense and homogeneous mass. Fiber reinforcement and silica fume can be added to shotcrete concrete to improve mixture characteristics. Fine aggregates will range from 60 to 70% of combined aggregates. The maximum size for coarse aggregate equal 3/8’’ (9.5 mm). Proper applying of shotcrete concrete will produce a sound concrete with good bonding. Shotcrete concrete is feasible and effective for thin sections and large areas. Shotcrete concrete will develop high strength, low water absorption, and low permeability if mixed and applied correctly. On the other hand, improper applying of shotcrete concrete will produce a weak concrete surface, vulnerable for chemical attacks which reduce the durability of the structure.

Figure 1

There is various application for shotcrete concrete. The success of shotcrete concrete is contingent upon planning, supervision, and skilled manpower.

- Repair: shotcrete can be used to repair damaged surfaces of concrete, steel, and even wood structures. Shotcrete can be used for rehabilitation of bridge deck, but it is uneconomical to use shotcrete for full-depth repair. It is useful to use shotcrete for repairing beams with variable depth, columns, and abutments. Shotcrete can be used for repairing fire and earthquake-damaged buildings. Also, it can be used to strengthen and repair deteriorated concrete surface.

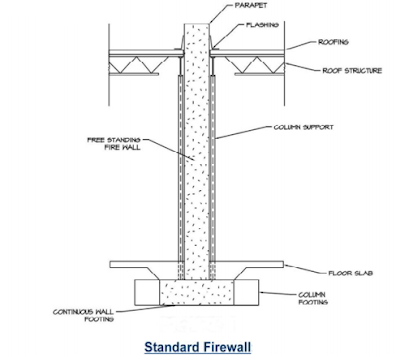

- Encasing of steel structure: shotcrete can be used to encase steel structure for fireproofing.

- Underground excavation: shotcrete concrete application in underground excavation ranges from supplementing or replacing support material such lagging, sealing rock surface, channeling water flow, and permanent lining.

- Slope and surface protection: shotcrete used to temporarily protect rocks that will deteriorate when exposed to air. Also, it is often used to cover slopes or cut. Proper drainage should be provided for the protected slopes or cut to prevent the uplifting pressure from damaging the shotcrete concrete.

- New structures: shotcrete used extensively to construct concrete swimming pools. Also, floors and overhead walls, slabs, columns, and other structural members. Shotcrete domes are another type of structure. The using of air inflatable formwork system have made the using of shotcrete concrete practical.

Shotcrete can be applied by two distinct applications. Dry-mix shotcrete and wet-mix shotcrete.

- Dry-mix shotcrete: the cementitious materials and aggregates are mixed in dry conditions and delivered to a pneumatic gun. The pneumatically operated gun will ensure a continues flow of the mix from the hose to the nozzle. The interior of the nozzle is fitted with a water ring which injects water to mix uniformly.

- Wet-mix shotcrete: the cementitious materials, aggregate, and water are mixed thoroughly as in conventional concrete. Then the mixture fed to delivery equipment such as a concrete pump. Then the mixture will be pumped through a hose to the nozzle. Additional air is added at the nozzle to increase the nozzle discharge velocity.

Figure 2

Figure 3

Wet-mix or dry-mix shotcrete has some difference in equipment cost, maintenance, placement characteristics, and product quality. These differences may make one of these methods more suitable for a specific application. The dry-mix produces a better bond with the existing surface compared to the wet-mix method. However, both methods produce a good bond with the existing surface. On the other hand, the rate of placing dry-mix shotcrete is much less than wet-mix shotcrete. The rebound or the material of shotcrete that bounce off from the shooting surface is less for wet-mix compared to dry-mix shotcrete. Air-entraining admixture can be used for the wet-mix method. The air-entraining admixture will be mixed through with the mix as in a typical concrete mix. However, dry mix shotcrete found to perform well in moderate exposure to freezing and thawing.

Comments

Post a Comment