Soundness test for aggregates

A soundness test is used to determine the ability of an aggregate to resist the weathering actions. This test used to determine the resistance of aggregate to disintegration due to cyclic soaking and drying in a magnesium sulfate solution.

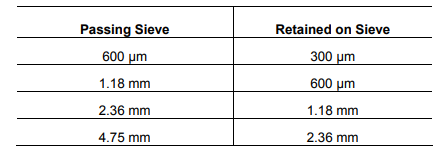

The soundness test can be conducted for fine or coarse aggregates. The sample of aggregate should represent the material to be tested. The fine aggregate should be passing sieve 4.75 mm. The preparation of fine aggregate sample will involve the sieving and washing of aggregate sample on 300 μmm then drying it. Then the sample will be sieved on the sieves shown in table no:1 for a period of 8 to 12 minutes. From the fractions obtained by the sieving, select samples of sufficient size of 100 grams from each. The obtained samples from each fraction will be sieved again to refusal then placed in separate containers. If the sample has less than 30% retained on the 300 µm sieve, it is deemed to be too fine, and no test is done on any fraction. If any fraction constitutes less than 5% of the sample, it shall not be tested.

Coarse aggregate should retain on 4.75 mm sieve. The coarse aggregate will be sieved into different sizes, and the quantity specified on table no:2 will be weighted out and placed in separate containers. If any fraction constitutes less than 5% of the sample, it shall not be tested.

The soundness test can be conducted for fine or coarse aggregates. The sample of aggregate should represent the material to be tested. The fine aggregate should be passing sieve 4.75 mm. The preparation of fine aggregate sample will involve the sieving and washing of aggregate sample on 300 μmm then drying it. Then the sample will be sieved on the sieves shown in table no:1 for a period of 8 to 12 minutes. From the fractions obtained by the sieving, select samples of sufficient size of 100 grams from each. The obtained samples from each fraction will be sieved again to refusal then placed in separate containers. If the sample has less than 30% retained on the 300 µm sieve, it is deemed to be too fine, and no test is done on any fraction. If any fraction constitutes less than 5% of the sample, it shall not be tested.

Table 1

Table 2

The test will start by placing each fraction obtained from fine aggregates into a separate wire basket. For the coarse aggregate, place the fraction between 4.75mm and 9.50 mm into a separate wire basket. Then place the combined fraction 19.00mm to 9.50 mm into a separate basket. Place combined fractions larger than 19 mm in one or more baskets as required. The second stage will begin by immersing the samples of aggregates into a solution of magnesium sulfate for not less than 16 hours and not more than 18 hours. The samples shall be immersed inside the solution at a temperature of 21±1c. Then the samples of aggregates will be removed and allowed to drain for 30 minutes. Then it will be dried in the oven at 110±5c until a constant mass is achieved. The cycle of soaking and drying will be repeated 5 times.

Figure 1

After the completion of test cycles, dry the sample, and wash the solution by the use of wash water with a 3% (by mass) barium chloride (BaCl2). The tested samples shall be sieved again, and the final weight of each sample should be determined. The percentage of loss for each sample will be calculated by the following equation;

Percent loss=((original mass-mass retained after test)/original mass)*100%

Comments

Post a Comment