Recycled aggregates

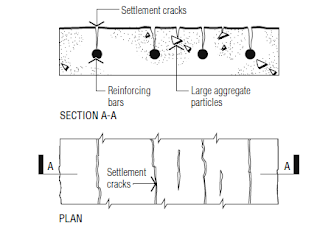

The steep growth of the construction sector resulted in massive consumption of earth resources. The using of recycled aggregates will help in preserving the environment. The construction waste amount increased rapidly in recent years. Undoubtedly, the recycling of construction waste such as concrete will help in safeguarding environments resources and ensure sustainability. Recycled aggregates can replace part of natural aggregates used in concrete. Natural aggregates can be replaced by 20% of recycled aggregates for all concrete classes, and 100% for a limited classes of concrete according to RILEM Technical recommendations. The using of recycled aggregates will produce concrete with lesser compressive strength and quality. Figure 1 construction management: concrete construction bridge construction:How to become a bridge engineer Most of the recycled aggregates produced from concrete waste. Aged concrete such as old foundation, bridges, building, and conc