Allowable stress and allowable load

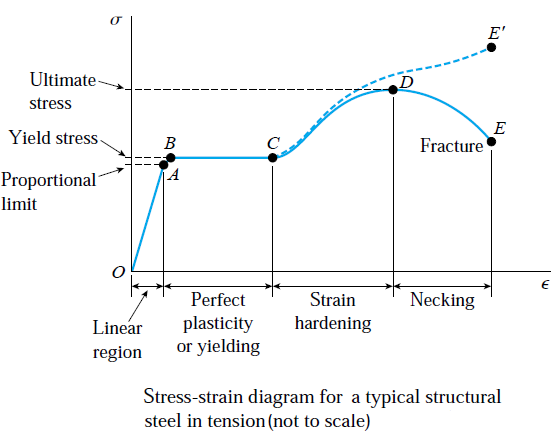

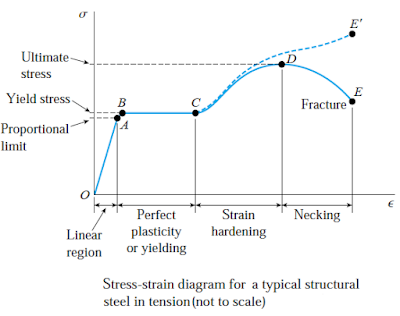

Designing a structure required a good knowledge of materials strength and load capacity. the required load to be supported or transfer by structure shall be less than the structure capacity. if the structure subjected to a load larger than it is capacity it will fail. therefore the actual strength of structure shall exceed the required strength. the ratio of the actual strength of the structure to required strength is known as the factor of safety. Ƞ=ِAcutual strength/required strength the factor of safety shall be higher than one. the factor of safety magnitude can range from slightly above 1 to 10 or more. Determining the magnitude of the factor of safety is difficult because strength and failure have a different meaning. actual strength of the material is the load and stress capacity of a structure. failure of a structure may mean the total collapse of the structure. or it could mean the excessive deformation of the structure. required load for the second case will be les...